Following the 2nd Call of the BSGN Advanced Materials and In-orbit Manufacturing Industry Accelerator in June 2025, three groundbreaking projects have been selected for acceleration and deployment in orbit: Starflight Dynamics, ArcSpace and Flawless Photonics.

Selected from a competitive pool of 18 applications across 10 ESA Member States, these projects aim to develop commercial solutions in advanced materials and in-space manufacturing domains by boosting their R&D through the unique properties of the space environment. During the Acceleration phase, The Business in Space Growth Network (BSGN), in collaboration with the Satellite Applications Catapult, the managing partner of the Advanced Materials and In-orbit Manufacturing accelerator will support the consortiums of this second cohort in refining technical and commercial plans, preparing the selected projects for implementation and deployment in orbit.

Who’s in the second cohort?

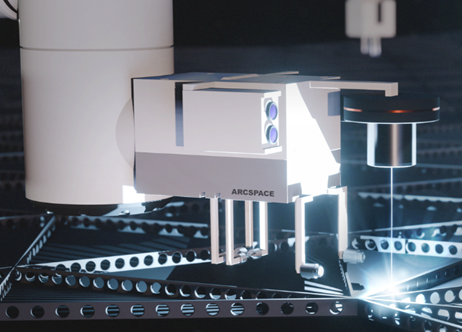

ArcSpace

Scalable in-orbit Electron Beam joining & cutting process for assembly & manufacturing operations

Lead Entity: ArcSpace (Startup, France)

Key Partners: CNRS – LPGP laboratory (France)

In-Orbit Manufacturing (IOM) is being held back due to the lack of available in-space tools/processes, preventing space mission and infrastructure designers from rapidly designing and testing breakthrough products. ArcSpace has developed a sustainable on-orbit joining and cutting solution based on Electron Beam technology, filling this capability gap for near-term in-orbit servicing applications, microgravity materials processing, and long-term in-space assembly of critical systems and large structures.

This mission will deliver a first-of-its-kind in-orbit demonstration of the company’s core welding technology, showcasing safe and controlled welding in microgravity through an innovative contamination-management approach. By proving this critical capability in space, the mission sets the stage for the commercial rollout of the company’s flagship offering: welding-based in-orbit servicing solutions designed to support sustainability and high-value dual-use applications.

Starflight Dynamics / Levion Materials

Zero-Gravity Growth of Next-Gen Semiconductor Materials

Lead Entity: Starflight Dynamics (Startup, Germany)

Key Partners: JX Advanced Metals Corporation (Japan)

Levion Materials (the newly established specialty division of Starflight Dynamics) aims to produce a new class of semiconductor materials by taking its manufacturing to space.

As disruptive effects like convection, segregation, and sedimentation driven by buoyancy are minimized under microgravity, this new approach leads to the formation of significantly defect-reduced crystals, resulting in ultra-pure materials of a quality fundamentally unachievable on Earth.

This concept builds on well-established growth methods (such as Travelling-Heater-Method and Bridgman technique) and combines precise thermal control with space-ready ampoule technology to create crystals ideal for next-generation electronics, sensing, and quantum applications among others.

Levion is therefore addressing the pressing demand for high-performance materials by paving the way for its space-enabled production.

This mission will demonstrate the crystal growth of advanced semiconductor materials – e.g., cadmium zinc telluride (CZT) and indium phosphide (InP) – inside sealed ampoules. A compact furnace module, pre-programmed to execute precise thermal cycles on 4 to 6 samples, will be used to replicate critical industrial crystal-growth processing steps under microgravity conditions.

The mission will validate not only material performance, but also system-level readiness – including hardware operability in orbit, safety of sealed charge handling, and post-mission recovery.

Flawless Photonics

Scaling ZBLAN Fiber Manufacturing from ISS Success to Autonomous Production in LEO

Lead Entity: Flawless Photonics (Startup, Luxembourg)

Building on their success aboard the International Space Station, where they produced nearly 12 kilometres of high-quality ZBLAN (zirconium barium lanthanum aluminium sodium fluoride) optical fibre—an unprecedented length for microgravity manufacturing – Flawless Photonics is now advancing toward fully automated, scalable in-orbit production. By leveraging microgravity to eliminate gravity-driven defects, Flawless Photonics’ next-generation systems will enable consistent, defect-free production of advanced optical materials, unlocking new opportunities in ultra-fast communications, sensing, imaging, and next-generation photonics.

Optical fibres are essential for our connected digital world. They are currently most commonly made of silica glass, which is easy to produce but requires the use of expensive repeaters due to optical losses in the fibre. Fluoride glass optical fibres, known as ZBLAN (zirconium barium lanthanum aluminium sodium fluoride), has significantly lower signal loss than silica fibres but is prone to crystallization defects when produced on Earth due to convection and other gravity-driven phenomena. In microgravity, these gravity-driven imperfections are eliminated, allowing for a purer, defect-free microcrystal formation, resulting in clearer glass. This purity can lead to a significant performance increase, opening new markets for infrared transmission and other high-end uses.

What comes next?

Throughout their acceleration journey, the selected project leads will benefit from dedicated 1-to-1 support by the Satellite Applications Catapult, gaining access to tailored support across all stages – from business maturation to the design of in-orbit demonstrations. This ensures both technical and commercial readiness for their missions.

Key advantages for the selected projects include:

- Expert guidance in navigating the complex space ecosystem, fostering connections with key stakeholders and resources.

- Assistance to refine private funding strategy beyond ESA support, while project leads retain final responsibility.

- Hands-on support in preparing documentation for ESA’s co-funding tools, simplifying the application process.

- Enhanced visibility and promotional support to amplify project exposure across relevant sectors.

This initiative underscores the commitment of the BSGN Industry Accelerator to propel innovation in advanced materials and in-orbit manufacturing, fostering collaboration and accelerating the journey from concept to orbit.

More information

About The Satellite Applications Catapult

The Satellite Applications Catapult is a UK-based innovation and technology centre dedicated to advancing the use of satellite data and services across industries. The Catapult helps businesses, governments, and research organisations harness space technologies to drive growth, sustainability, and digital transformation. Through the Beyond Earth mission, the Catapult is working with businesses and research organisations to develop technologies that enable satellite life extension, debris removal, autonomous assembly, and in-orbit manufacturing. By fostering collaboration and providing access to cutting-edge facilities, the Catapult is helping UK and European companies shape a new era of space infrastructure and capability beyond Earth.

About ESA

The European Space Agency (ESA) provides Europe’s gateway to space. ESA is an intergovernmental organisation, created in 1975, with the mission to shape the development of Europe’s space capability and ensure that investment in space delivers benefits to the citizens of Europe and the world. By coordinating the financial and intellectual resources of its members, ESA can undertake programmes and activities far beyond the scope of any single European country.

About BSGN Advanced Materials and In-orbit Manufacturing Accelerator

The BSGN Industry Accelerators are part of an ESA initiative designed to drive the growth of new economic markets in Low Earth Orbit and on the Moon. These accelerators facilitate collaboration with key industry players, attract new market entrants, and support the development of commercially viable business models based on space research. Operating under a public-private co-funding model, the BSGN Advanced Materials and In-orbit Manufacturing Industry Accelerator is managed by ESA’s Industrial Partner the Satellite Applications Catapult. It focuses on co-funding and supporting commercial projects and innovators developing breakthrough advanced materials and manufacturing solutions using in-orbit R&D and microgravity engineering platforms.

JOIN OUR ORBIT

Stay in the loop

Be the First to know about news, events, and other opportunities