Space Forge

-

- Research & Product Development,

- In-Space Manufacturing,

- In-Orbit Demonstration and Verification,

- Testing & Qualification,

-

- Microgravity,

- Vantage Point,

- Cosmic Radiation,

- Extreme Temperature,

- https://www.spaceforge.co.uk/

-

Wentloog Avenue, Cardiff, Wales, CF3 2EY, United Kingdom

- Low-Earth Orbit (LEO)

- ForgeStar

Service Description

Space Forge is transforming return from space to enable revolutionary products, for the benefit of humanity.

The ForgeStar vehicle is a low-cost, independent, reusable space vehicle, which can perform scalable manufacturing in orbit. It will develop and manufacture new materials and products, for space alongside non-space organisations, who can then reap the benefits of in-space manufacturing for industries across the globe.

In-Space Manufacturing Benefits

Manufacturing on Earth is difficult for a number of reasons. Gravity prevents perfect alloying in materials, the dense atmosphere creates contamination in even the cleanest of processes, and extreme temperatures are difficult to maintain.

In-space manufacturing offers a range of benefits due to weightlessness, vacuum, and near-zero temperatures. These conditions allow for perfect crystallisation, remove contaminants from the manufacturing process, and the freedom to access low temperatures without requiring cryogenics.

This creates an unmatched manufacturing baseline for any material. Space Forge’s return technology reduces the cost of return from space, which means less space debris in the orbital environment, and enables satellites to be refurbished on Earth for the first time ever.

The Backstory

In-space manufacturing is not a new idea. Since the days of the Soyuz, astronauts have been undertaking basic experiments to discover the effects of microgravity on manufacturing processes. From there, Skylab, as well as the Space Shuttle carried out further experimentation.

The International Space Station has continually championed in-space manufacturing, and carried out a few experiments. However, the issue with this is that the ISS orbit is contaminated, as LEO has been used continuously for satellite operations, leaving debris and pockets of oxygen. Additionally, having humans on board limits the number of in-space manufacturing operations that can be carried out, since many large scale or dangerous operations would not be safe.

Microgravity as a service

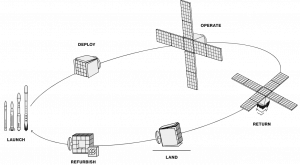

The ForgeStar vehicle will be launched into space, complete manufacturing operations autonomously, then be returned to Earth aided by a novel heat shield, as well as a specialised capture system. The process has been designed specifically for the most sensitive of products to be returned intact and undisturbed.

Applications

In-space manufacturing benefits industries which require high performance and efficiency levels in power-hungry infrastructure and systems. Some of the initial markets which will make use of the ForgeStar include advanced materials, electronics, and pharmaceutical sectors.

Space manufactured alloys can be used to create bigger, stronger turbines on aircraft so that planes use less fuel, more efficient batteries can also be created for electric planes or cars.

Wind turbines, for example, are more efficient the larger they are, but have to be made in pieces so they can be transported to a site for installation, and then held together with bolts. By making bolts that are stronger than what can be manufactured on Earth, it’s possible to develop a larger, more efficient wind turbine that can create more energy.

Aether

To help with the return of the ForgeStar platforms, Space Forge is also developing a predictive analytic tool that is an order of magnitude better at providing satellite and space body re-entry landing locations. This will ensure that satellites returning to Earth will be captured accurately, to keep on-board materials safe, and enable the satellite to be reused.

Vision

Space Forge is aiming for responsive launch and tactical return when it comes to the development and delivery of novel materials. The ForgeStar will establish Europe as a world leader in operational return from space, making it one of five global destinations with the capability.

Ultimately, Space Forge aims to lead the push towards a space based economy, by allowing industries around the world to leverage the benefits of microgravity. In the run up to the commercialisation of the ForgeStar vehicle in 2023, Space Forge will be connecting with new industries to inform them of the benefits of in-space manufacturing, thus enabling more potential customers to revolutionise their products.

In the Media

See also