Voyager Technologies Europe

-

- Voyager Technologies Europe

-

- Research & Product Development,

- In-Space Manufacturing,

- In-Orbit Demonstration and Verification,

- Mission Support Services,

- Testing & Qualification,

- Microgravity Research,

-

- Microgravity,

- https://voyagertechnologies.com/space-solutions/

-

2, Corso Valdocco, Torino, Piemonte, 10122, Italy

- Low-Earth Orbit (LEO)

- ISS

Service Description

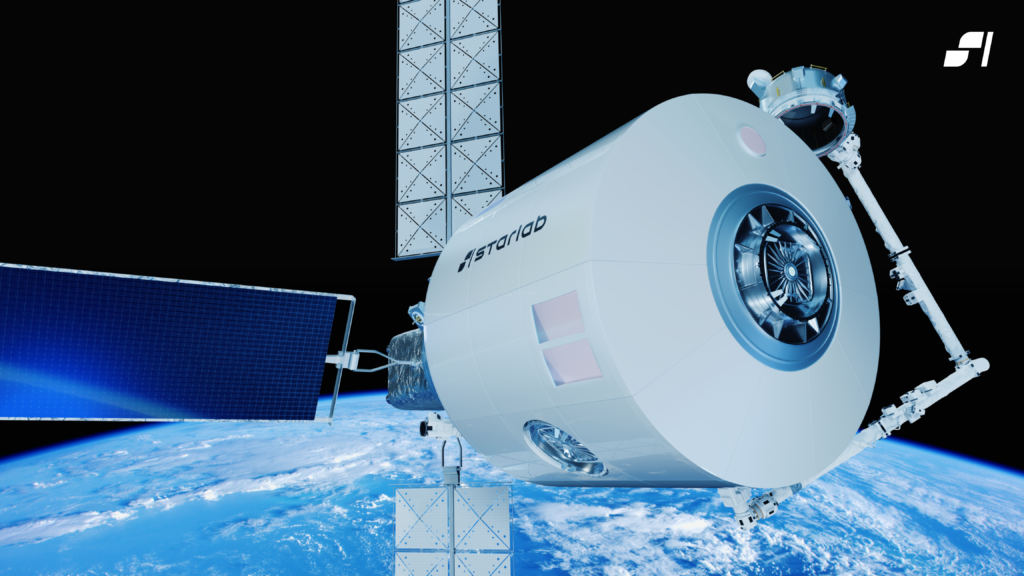

Voyager Technologies Europe, active for over a decade in the space sector, operates through three strategic divisions: Defense & National Security, Space Solutions (which includes its European division – Voyager Technologies Europe – active in Italy since 2018), and Starlab, the next generation commercial space station.

Specializing in advanced technologies, Voyager manages scientific experiments aboard the International Space Station (ISS), with over 2,000 payloads flown to date, and develops critical infrastructure for government, commercial, and scientific missions, ranging from low Earth orbit to space exploration.

The company operates under a Space Act Agreement with NASA, a partnership framework that enables collaborative research and technology development on the ISS.

Core Services

Voyager Technologies Europe, based in Turin, provides hosting of scientific experiments aboard the International Space Station (ISS), offering a unique environment for autonomous testing or direct astronaut-assisted, alongside satellite deployment services in low Earth orbit (LEO).

Specifically, the company offers:

– Payload designing support

– Launch and access to the ISS;

– The utilization of proprietary facilities aboard the ISS;

– Payload design and development;

– Manifesting and safety review

– Clean room and testing

– In-orbit payload operations

– Payload returns from the ISS.

A comprehensive approach that combines cutting-edge research and operational solutions for government, commercial, and scientific space missions.

Key solutions

NanoLabs/Nanode

Nanolabs are the original commercial plug and play microgravity research module located inside Nanode, Middle Locker designed to be installed in Express Rack. Think outside the box – but fit it inside the box. Nanolabs are low-cost, open-sourced, standardized, hardware with integrated power and data connections.

BlackBox

BlackBox is a remotely commanded platform that has research fully integrated on the ground and completely contained by the astronaut crew. All the astronauts have to do is plug the entire locker-sized platform in on-orbit for power and data. BlackBox allows for multiple experiments to occur simultaneously.

Bishop Airlock

Bishop’s design prioritizes scale, safety, and mission diversity, enabling operations that traditional airlocks cannot support. Key features:

1. Unmatched Capacity & Versatility: Bishop’s 144U payload volume (over 5x larger than legacy airlocks) allows multiple experiments, satellites, or equipment to be deployed or retrieved in a single mission. Its cavernous interior accommodates payloads up to 112 x 112 x 127 cm and masses up to 322 kg, enabling everything from bulky maintenance tools to clusters of SmallSats.

2. Satellite Deployment, Simplified: Bishop is a game-changer for SmallSat operators. Its large volume supports diverse satellite configurations in one solution. Deployments occur during orbital daylight for real-time visual confirmation, ensuring payloads safely exit the ISS. Ground teams manage the entire process post-installation, astronauts simply prep payloads, and the Space Station Remote Manipulator System (SSRMS/Canadarm2) robotically positions Bishop for operations.

3. Microgravity Research & Exposure: Bishop isn’t just a transit hub, it’s a lab. Host experiments in microgravity, expose payloads to space, or test hardware in variable pressures (from 14.7 psi to vacuum). With Ram, Wake, Zenith, or Nadir pointing options, researchers optimize conditions for thermal, radiation, or aerodynamic testing. Need a hybrid environment? Operate with the hatch open to the ISS or sealed for controlled isolation.

4. Pressure Flexibility

Unique to Bishop, payloads can operate in any pressure condition, from full vacuum to ambient station pressure. Test materials, sensors, or biological samples in incremental steps or extreme environments, all without risking crew safety.

5. Spacewalk Support

Bishop acts as an external “toolbox” for astronauts. Large equipment (e.g., replacement parts, instruments) is robotically prepositioned outside the ISS, reducing crew time and risk during EVAs.

Why Choose Bishop Airlock?

• Cost & Risk Reduction: Skip the satellite build. Test your tech in space faster using Bishop’s plug-and-play infrastructure. Focus on data, not launch logistics.

• Infinite Pointing: Canadarm2 positions Bishop to face any direction—perfect for Earth observation, deep-space experiments, or minimizing orbital debris risks.

• Mission Agility: Combine payload types (research, satellites, tools) in one mission. Maximize value per sortie.

• Crew Safety First: Hazardous or complex operations are managed remotely, keeping astronauts focused on critical tasks.

Bishop isn’t just for the ISS. Its design principles, standardization, scalability, and robotic integration are paving the way for next-gen airlocks on commercial stations, commercial habitats, and deep-space missions.

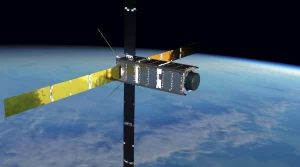

Nanoracks CubeSat Deployer (NRCSD)

Our cubesat deployer is a self-contained system that has been in operation since 2014. The deployer consists of anodized aluminum plates, base plate assembly, access panels, and deployer doors. The NRCSD deployer doors are located on the forward end, the base plate assembly is located on the aft end, and access panels are provided on the top. The inside walls of the NRCSD are a smooth bore design to minimize and/or preclude hang-up or jamming of cubesat appendages during deployment.

KABER

Our Kaber MicroSat Deployer enables deployment for a class of payload developers normally relying on expendable launch vehicles for space access. MicroSatellites that are compatible with our Kaber Deployer have additional power, volume and communications resources enabling deployment missions in low-Earth orbit of greater scope and sophistication.

Education & Research Programs

Voyager promotes programs for universities and schools, offering accessible hardware (e.g., DreamCoder 2.0 boards programmable in Python or Mixstix platforms) and opportunities to conduct parallel experiments on the ISS.

MixStix

MixStix, a simple platform that delivers big results. These are test tubes for space, activated by astronauts, and brought back to Earth for analysis. Mixstix are mixture enclosure tubes for fluids, materials, chemicals and biological substances – all kept separate until they are ready to be mixed in space. Single, double, or triple experiment sample segments are available. Astronauts release the block on the chambers and shake the tube to mix the materials. All Mixstix are 10 ml parylene coated silicon tubes. Mixstix can be stowed cold (+4°C), or ambient on launch, berth, pre/post operations, and on payload return to Earth.

Autonomous Platform Development

The company is expanding operations into orbits ideal for scientific research, developing dedicated cargo platforms for experimentation to ensure flexibility and responsiveness to emerging needs in the LEO space sector.

Significant Achievements

Orion ROCKY

The Orion ROCKY is an ultra-compact exercise device (size of a shoebox, ~20 lbs, 1 ft³) designed for NASA. It converts astronauts’ movements into rotational energy, providing adjustable resistance up to 400 lbs and supporting exercises like rowing, squats, and lifts. Built for extended space missions, it aims to revolutionize microgravity workouts with a versatile, efficient approach.

GITAI

GITAI showcased its robotic systems in the Bishop Airlock for in-space servicing, assembly, and manufacturing (ISAM), aiming to reduce astronaut tasks. The upcoming mission will test durable space-environment robots and a full airlock cycle, advancing orbital automation capabilities.

Cosmic Radiation Meets Seed Development

FAO and IAEA studied cosmic radiation and microgravity’s impact on plant genomes to induce genetic mutations for climate-resistant crops. The space-based research aims to enhance breeding techniques and accelerate sustainable agricultural adaptation.

SOARing To New Heights

The SOAR satellite, a 3U CubeSat led by the University of Manchester (DISCOVERER project), studies the residual atmosphere and gas-surface interactions in very low Earth orbits (VLEO). It aims to test innovative materials to reduce aerodynamic drag, optimize satellite performance, analyze atmospheric flow, and demonstrate aerodynamic attitude control manoeuvres, paving the way for more efficient missions in low Earth orbits.

Voyager and MSG Sphere Studios Launch Camera to the ISS

Voyager and MSG Sphere Studios have launched a high-resolution 360° camera to the International Space Station (ISS) to create immersive visual content for venues like Las Vegas’ Sphere. The project merges space exploration with creative innovation, offering unique Earth perspectives and pioneering new storytelling possibilities in microgravity.

Adidas-Boost in Space

Adidas partnered with Voyager and NASA to test Boost midsole production in microgravity, analyzing pellet behavior during mold filling via high-speed cameras. The experiment, free from Earth’s gravity, aimed to optimize shoe performance and comfort. Returned molds will guide future innovations in running technology.

Nanoracks-Europe Spearheading DreamCoder™ 2.0, with European Space Agency Support

DreamCoder 2.0 is a project for students impacted by the pandemic. It enables them to develop and execute code on the International Space Station (ISS) through a hardware platform that collects data such as humidity and temperature. The 2.0 update integrates cloud computing, making it accessible from home. Born in response to the educational challenges posed by COVID-19, the project engages schools and universities across multiple cities, fostering STEM education and global public-private collaboration. Its goal is to inspire students with hands-on space experiences, even remotely.

Voyager in the Media

Relevant documents

Get in Touch

For more information, reach out to eu.info@voyagerspace.com